Delinker

Project Overview

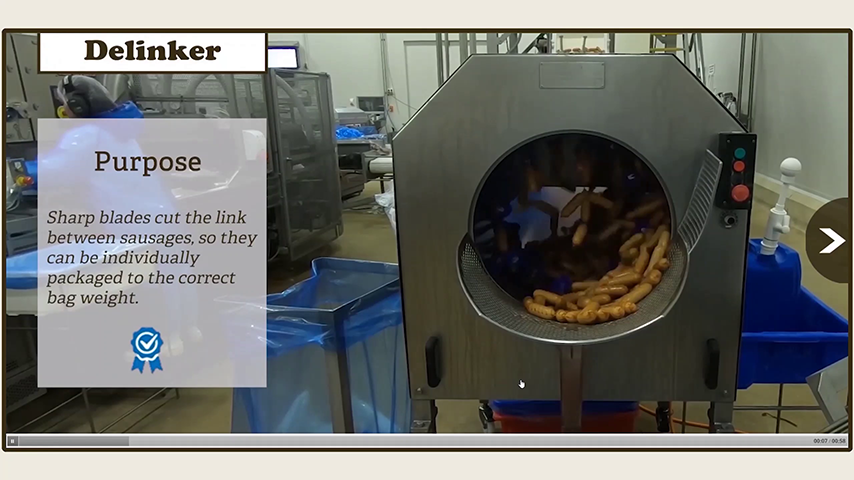

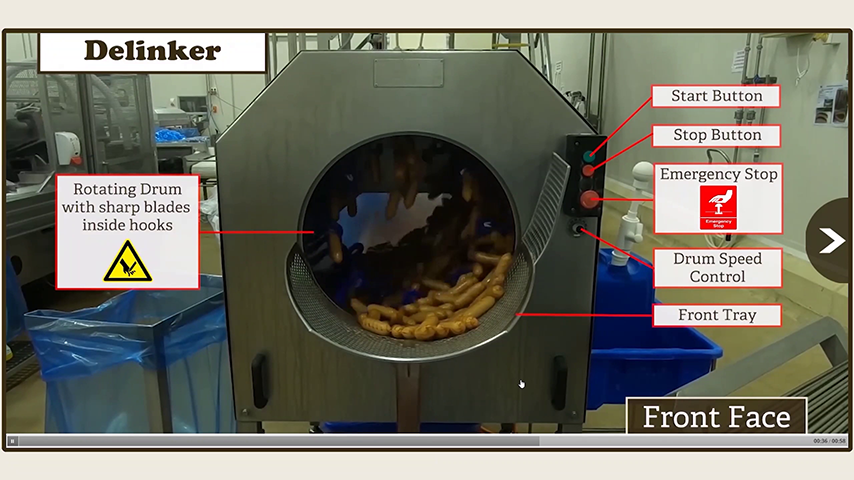

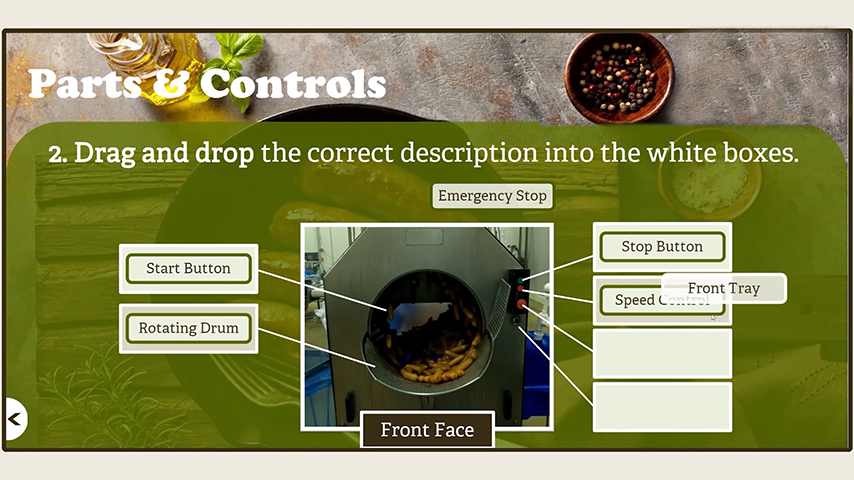

Our team embarked on the development of a dynamic e-learning module dedicated to educating individuals about the safe

operation of machinery, with a specific emphasis on the delinker—a commonly utilized sausage-separating machine within

the food manufacturing sector. While it may not fall under the high-risk machinery category, it demands authorized

personnel with competence in handling its electrical components and moving parts

Project Details

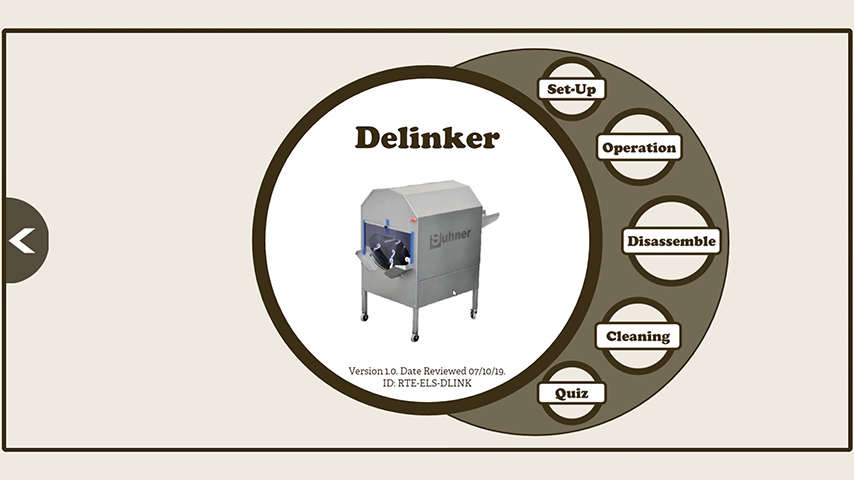

The primary challenge we encountered was striking the right balance between providing essential safety information and

covering the machine's functional stages, ensuring trainees could handle excessive technical content. To achieve this,

we structured the module into four main sections:

- Set-Up: This section guides trainees through preparing their workstations and assembling all the necessary parts

as they gear up for production.

- Operation: Here, we cover the fundamental aspects of running the machine, focusing on crucial safety protocols

for personnel and maintaining food quality standards.

- Disassemble: As production concludes, trainees learn how to safely disassemble the machine, ensuring that all

parts are removed for proper cleaning.

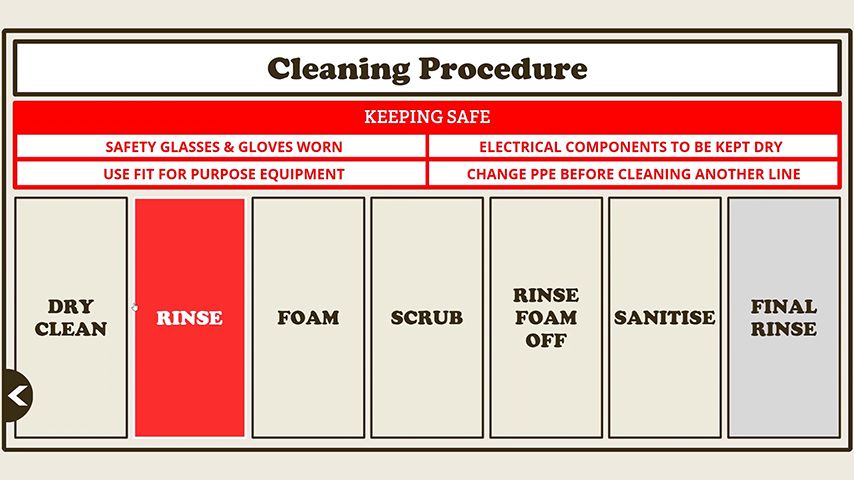

- Cleaning: This critical section serves as the culmination of the workflow, focusing on equipping trainees with

the necessary guidance to thoroughly and safely clean each component of the machine. Following our step-by-step

instructions, trainees learn the best practices to ensure the machine's optimal condition and readiness for seamless

production the following day.

Skills and Technologies

Storyline 360

Trello

Adobe Photoshop

Adobe Premiere

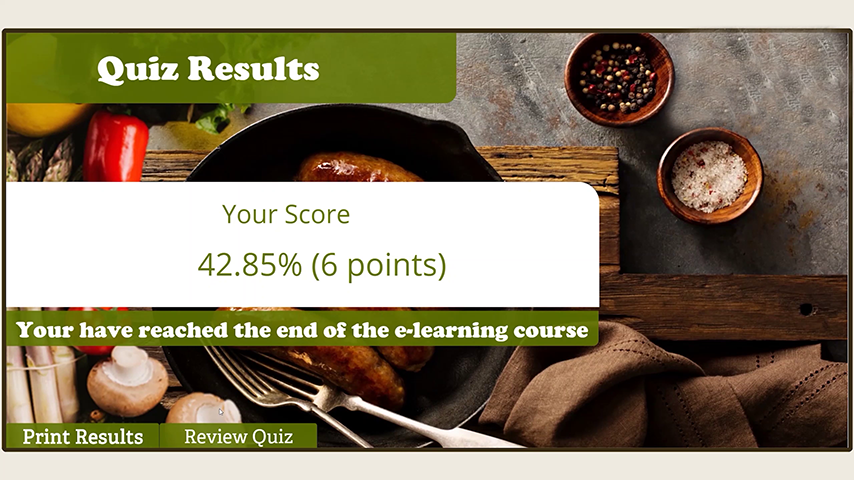

This module concludes with a comprehensive quiz that actively involves the audience to enhance engagement and evaluate

knowledge retention. This e-learning module was meticulously crafted using Storyline 360, an industry-leading authoring tool, and

Adobe Premiere Pro for video editing, ensuring a high-quality learning experience.